Top 7 Applications of an Actuator and Why You Need One Now

By TOI Staff

February 13, 2023

Update on : March 4, 2023

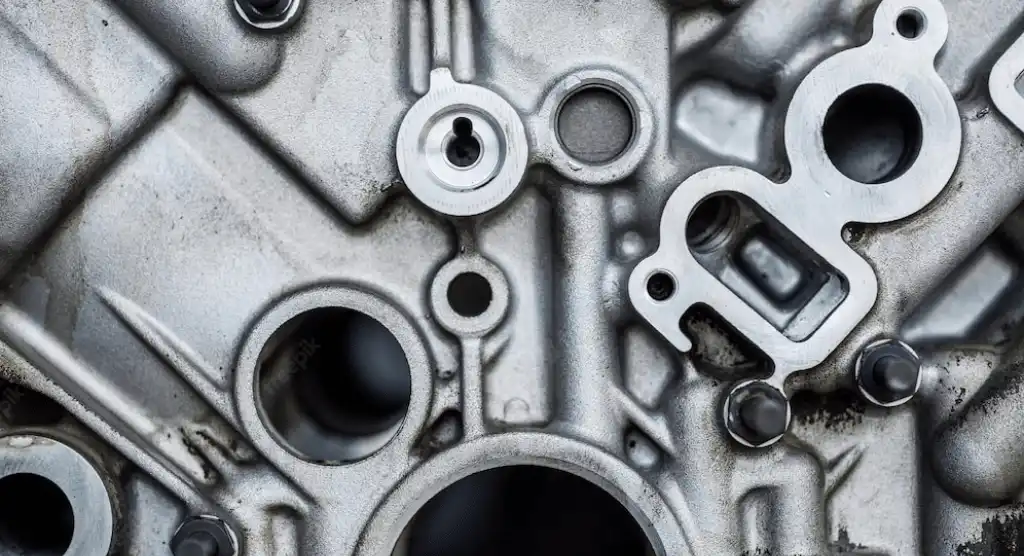

An actuator is an electrical device used to control the position of a joint in an assembly. An actuator is a computer-controlled version of a simple valve. The typical application that uses a servo-driven electric motor and gearbox is in engineering systems to control the position of mechanical assemblies with minimal force and maximum speed.

An actuator can be applied with many actuators, such as linear, rotary, pneumatic, hydraulic, or electric solenoids. The simple principle of an actuator is to convert electrical energy into mechanical energy. Here are the top seven applications of an actuator and why you need one now.

1. Material Handling

Actuators work to keep your materials and tools in order. You can create different levels of force, speed, acceleration, and deceleration controlled by the computer to adjust the lifting height and speed of your materials with minimum energy. Of course, this mechanism depends on the material handling system you want to make. The main benefit is that you can simultaneously control an object’s size and shape.

2. Robotics

Actuators work for your remote-controlled robots. One of the major applications of actuators is their low weight and high speed. You can easily control actuators, and they are easy to install. Actuators are used as linear motors, AC servos, or DC servos to move a part in a structure with a computer using rotary technologies. They can be applied in different ways, such as milling machines, CNC lathes, and drilling machines.

3. Window Automation

You can control the window by using an actuator, and you can control the opening and closing of a window. It’s a versatile application that includes doors, appliances, fans, etc. In addition, you can pick up an object from your hand or floor and move it from one place to another. It is a very common use of actuators for robotic applications to pick up objects such as food products and bottles, transport containers, etc. This may be helpful in medical research.

4. Agricultural Machinery

In agriculture, actuators are designed for moving farm machinery and equipment. There are different applications such as lifting, drilling, and pulling machinery. Actuators adjust your machine’s speed according to the object’s operation. Depending on an actuator’s application, it can be essential in water irrigation systems.

5. Solar Panel Operation

You can use an actuator to open and close a lid for solar applications. During the operation of the solar panels, you can use this application to adjust the panel’s position. You can also design your system at home with a simple motor unit for controlling the opening and closing of your solar window or door. Installing actuators linear will help you reduce the overall operating costs and energy consumption.

6. Food and Beverage Manufacturing

This application of an actuator is widely used in the manufacturing industry, where you are using a machine to pick up something from the floor. In this application, you can use a conveyor or lifting system for your food products. You can also apply this technology to moving your material from one place to another in almost every field.

7. Cutting Equipment

In manufacturing machinery, linear actuators are used in the cutting process. It is a very common application of an actuator in which you can cut something with more force and speed to make your work more efficient. You can use an actuator throughout your work. Actuators have been used for industrial purposes and in many automated systems. They may be a cheap option compared to other automatic systems, but they offer reliable operation and strong performance to satisfy your business needs.

Conclusion

Multiple types of item handling equipment are available for the manufacturing and material handling industry. The proper application of actuators can be helpful in any industry. Actuators are a very good option to automate your machines with less power and high performance. Many systems will help you increase your automated machinery’s efficiency and reliability, which will ultimately help your business grow. In addition, they can reduce the time frame and energy costs during work.